Technical Resources

Looking to get more out of your industry-leading Falcon Asphalt equipment? We offer a range of asphalt repair technical resources to help you boost efficiency and limit expensive on-site downtime. Read on to learn more about our smart equipment design, parts and maintenance services, and extensive online documentation library.

Asphalt Recycling

Protecting original oils is the key to returning asphalt to its original state. Our patented technology uses radiant heat to break down leftover asphalt, chunks, and millings.

Hardened asphalt is mixed with a rejuvenator and heated overnight at a low temperature to ensure the original oil content is retained. By using gentle indirect, radiant heat, Falcon solved the problem of oil loss caused by recycling with a direct open flame.

Docs & Manuals

Explore our comprehensive library of documents and manuals for our full range of equipment. Learn how to operate your equipment for maximum efficiency and quality results, or start here when troubleshooting a unit that is not performing as expected.

Service Parts

Falcon carries a full line of service parts for its asphalt recyclers and hot boxes. Call or email us to discuss your needs. We’re able to ship most parts on the same day.

VIP Technology

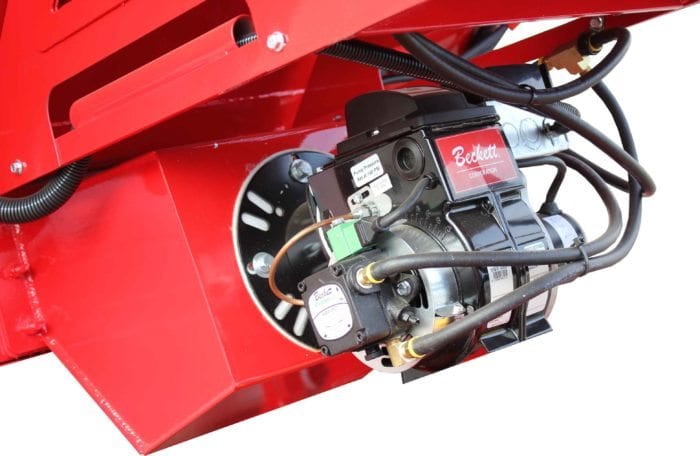

Running a diesel burner below the required battery voltage can result in no-starts, dirty CAD cells, increased fuel consumption, and burner component damage. No-starts can also lead to a build-up of fuel in the combustion chamber that can ignite and melt plastic components.

Falcon’s patented Voltage Indicator and Protector (VIP) technology automatically prevents the burner from operating below the burner manufacturer’s required voltage, protecting your burner and CAD cells.

Ask Us About Our Technical Resources

For Falcon Asphalt, providing you with the best asphalt repair equipment on the market is just the beginning. We back up our quality products with a full range of technical services from critical advice and maintenance services to genuine parts and product documentation.

Need help getting the most out of your Falcon Asphalt equipment? Click below to get started.